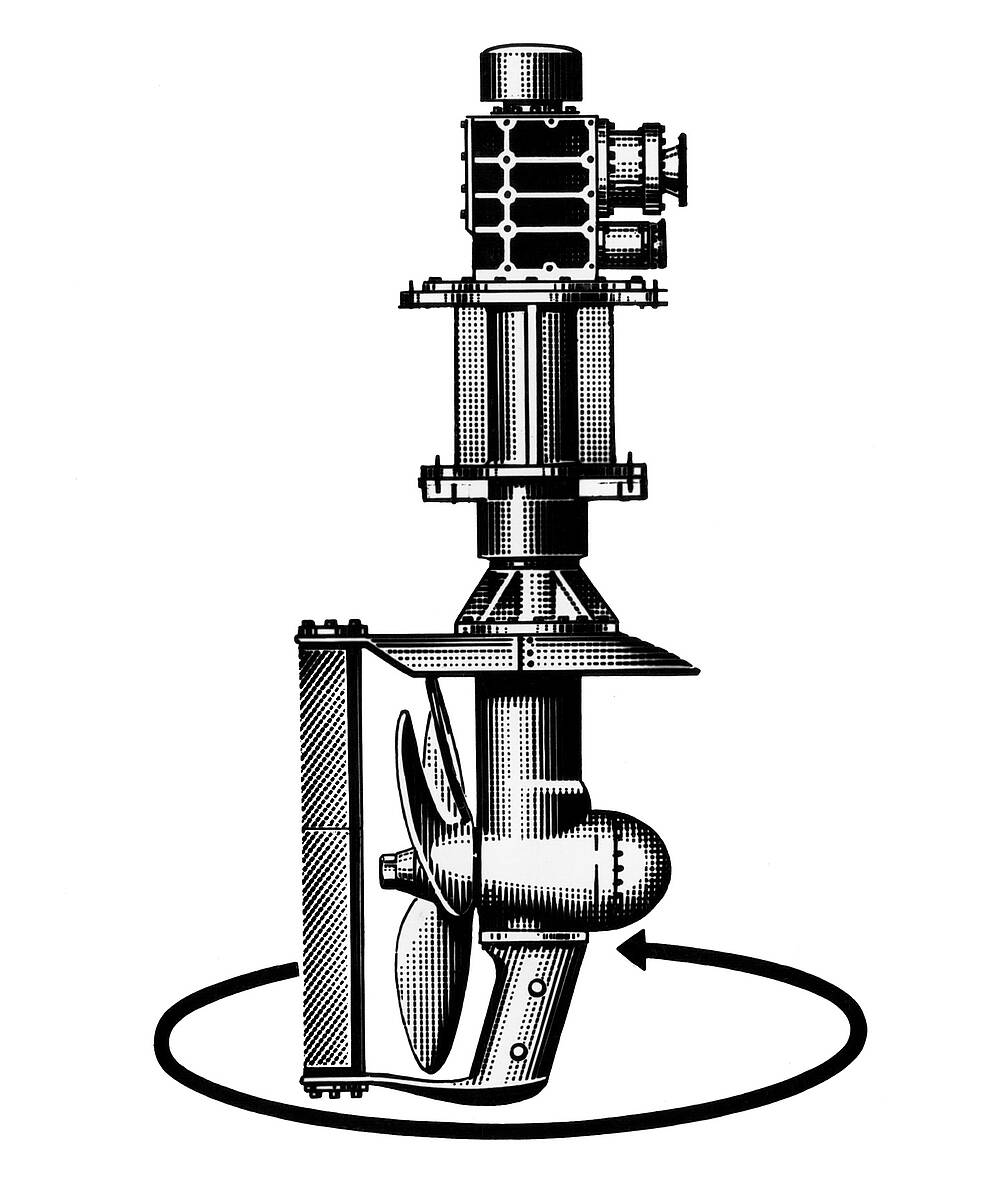

SCHOTTEL founder Josef Becker invented the fully steerable rudder propeller – marking the beginning of SCHOTTEL’s global success as a manufacturer of innovative marine propulsion systems. The SRP has been in use worldwide ever since. This revolutionary invention recently celebrated its 75th anniversary.

Driven by a deep interest in technology and shipbuilding, company founder Josef Becker sets out to develop a new combination of propulsion and steering despite never having formally studied engineering. Model tests are carried out in a bathtub.

The first rudder propeller (150 hp/110 kW) is installed in the company’s own boat Magdalena, named after Josef Becker’s wife.

With the SRP, a ship has the full power of its propulsion engine available for manoeuvring for the first time without the need for a separate rudder blade. The police boats (see 1952) turn at full speed in just 1.5 boat lengths and turn almost on the spot at slow speed. A 180° turn of the propeller is sufficient to change from “full ahead” to “full astern”.

Ships equipped with SRPs belonging to the Rhineland-Palatinate water police are deployed during a flood disaster in the Netherlands. Their exceptional manoeuvrability causes a sensation and leads to several orders from the local water police. The following year, the first major order for 15 ships for the French Rhine Army is received – marking an international breakthrough.

On 23 November 1955, the then-SCHOTTEL shipyard receives patent no. 1025293 for the ‘steerable propeller propulsion system for ships with outboard motors’.

Offshore oil production requires vessels that can be positioned with absolute precision. The French core drilling vessel Trebel is thus equipped with the world’s first dynamic positioning system. Two SRP 150 units ensure maximum manoeuvrability.

Numerous further developments of the SRP followed for almost all types of vessels used in oil and gas exploration: they keep production platforms, support and supply vessels, cable and pipe layers, and specialized vessels such as hydrographic survey vessels and diver support vessels in position, even under the most challenging weather conditions. By 2015, the market share for platform supply vessels will grow to 20 percent. The offshore market is just one of many whose development has been significantly influenced by the SRP – both then and now.

Together with a Hamburg, Germany-based shipping company, SCHOTTEL develops the first harbour tug with a rudder propeller: the Janus, which is still in service today as Jan Leenheer. Market acceptance is reflected in good sales figures.

The development of the newly designed stern tug, whose requirements are perfectly met by the SRP, and the simultaneous internationalization of the company fill the order books.

The Azimuth Stern Drive (ASD) tug offers the advantage of a lower draft compared to tractor tugs and can be steered and handled more precisely. By the end of the 1980s, 80 percent of the tugs equipped by SCHOTTEL are stern tugs.

The world’s largest offshore crane vessel, the Micoperi 7000, is fitted with underwater-mountable SRP 4500 units – the most powerful rudder propellers in the world at the time.

Ever larger container ships demand ever higher bollard pull from harbour tugs. The new SRP 1515, designed to meet these demands, is an instant success. By 2025, around 1,300 units of this thruster, now renamed SRP 460 / SRP 490, will have been delivered thus making it the most successful azimuth thruster in the world.

The design principles of the SRP have had a significant influence on azimuth technology in the global maritime market. At SCHOTTEL, it has paved the way for the development of additional main and auxiliary propulsion systems, each of which is tailored to the diverse operational profiles of modern vessels. Alongside the SRP, customers choose other main drives, such as the controllable pitch propeller (SCP) or the azimuth pull propeller (SCHOTTEL EcoPeller), as well as a wide range of auxiliary drives.

With over 600 equipped tugs, SCHOTTEL is the market leader with its SRP.

After intensive research and development in cooperation with the Dresden University of Technology, Germany, the HTG high-performance gearbox is introduced to the market in 2016. Among other improvements, it enables drive torque to be increased by up to 15 percent with the same bevel gear dimensions.

The HTG (High Torque Gear) extends the service life of the gearbox, resulting in significant gains in performance and safety. State-of-the-art milling and calculation methods are used to achieve shapes that enable a highly efficient, robust and safe gearbox with an ideal gear geometry.

The anodes required for corrosion protection are repositioned in the rear cross-section of the nozzle. The “ProAnode” enhances hydrodynamic flow characteristics and offers economic advantages. Additionally, it lends the SRP a distinctive and recognizable appearance.

For 75 years, the SRP has demonstrated its reliability across a wide range of vessel designs and operational profiles requiring maximum manoeuvrability, exceptional bollard pull, and/or outstanding course stability during free sailing. With more than 17,000 units installed in over 120 different vessel types, the SRP has become the benchmark in propulsion systems.

SYDRIVE offers both mechanical and electrical hybrid drive solutions for the SRP, delivering numerous operational and environmental advantages. The new concept is successfully introduced to the market. In 2025, the delivery of four SRP 710 units equipped with SYDRIVE-M, each providing a bollard pull of up to 120 tonnes, marks SCHOTTEL’s most powerful hybrid propulsion system to date.

The responsive SRP-D is launched. By the anniversary year, more than 50 units have been sold. It provides indispensable support for vessels involved in the commissioning and maintenance of offshore wind farms.

The SRP-D features a propeller shaft inclined at eight degrees and a vertically integrated electric drive motor (“embedded L-Drive”). Its shorter response times enable faster and more precise reactions to external forces such as wind and currents, resulting in improved vessel positioning accuracy. Vessels equipped with the SRP-D operate more efficiently and safely, with extended operational availability throughout the year.

According to recent market studies, SCHOTTEL rudder propellers power well over half of the world’s fully electric tugboats and also hold a leading position in the hybrid tugboat segment.