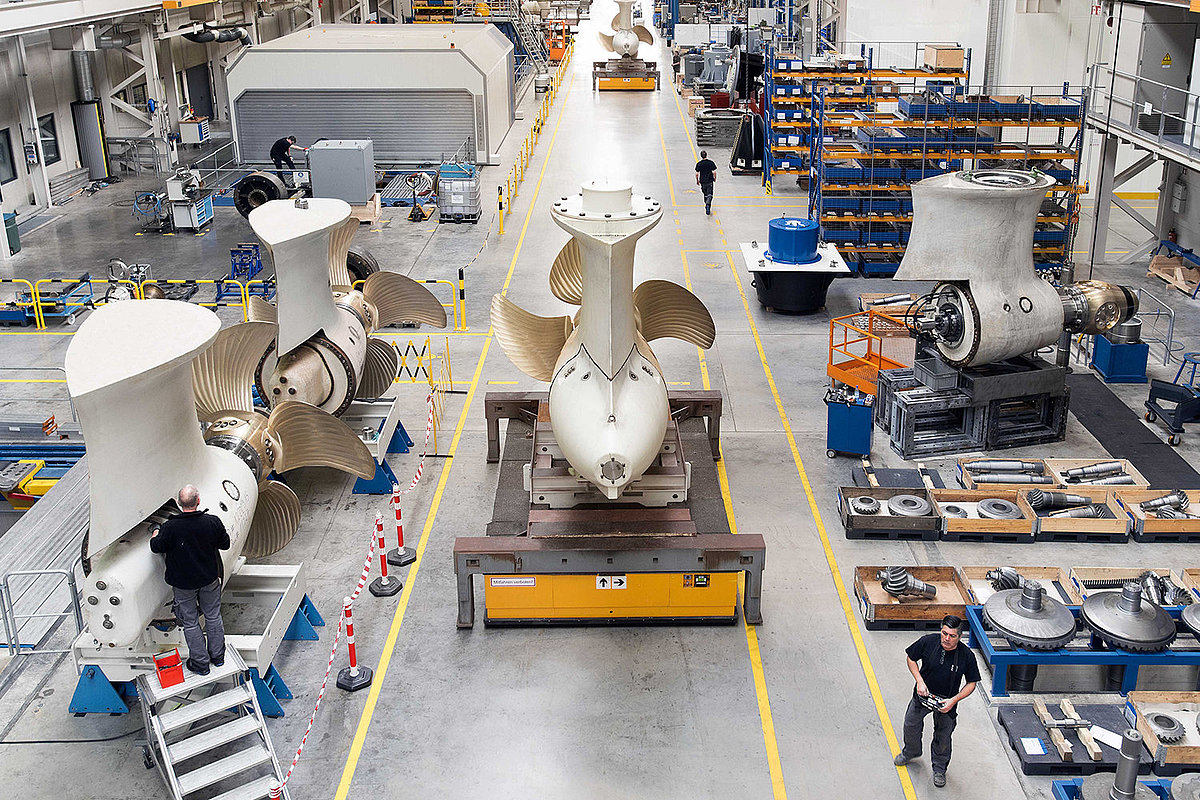

High-performance nozzles from SCHOTTEL are used in various types of vessels and applications to boost the propeller’s thrust force. Based on decades of propulsion expertise, SCHOTTEL VarioDuct (SDV) and SCHOTTEL CruiseDuct (SDC) feature impressively high outputs during free sailing and excellent bollard pull values. Part of this is the state-of-the-art technologies used to ensure the high performance characteristics of the nozzles.

The new nozzles are equipped with the exclusive ProAnode technology from SCHOTTEL as standard.

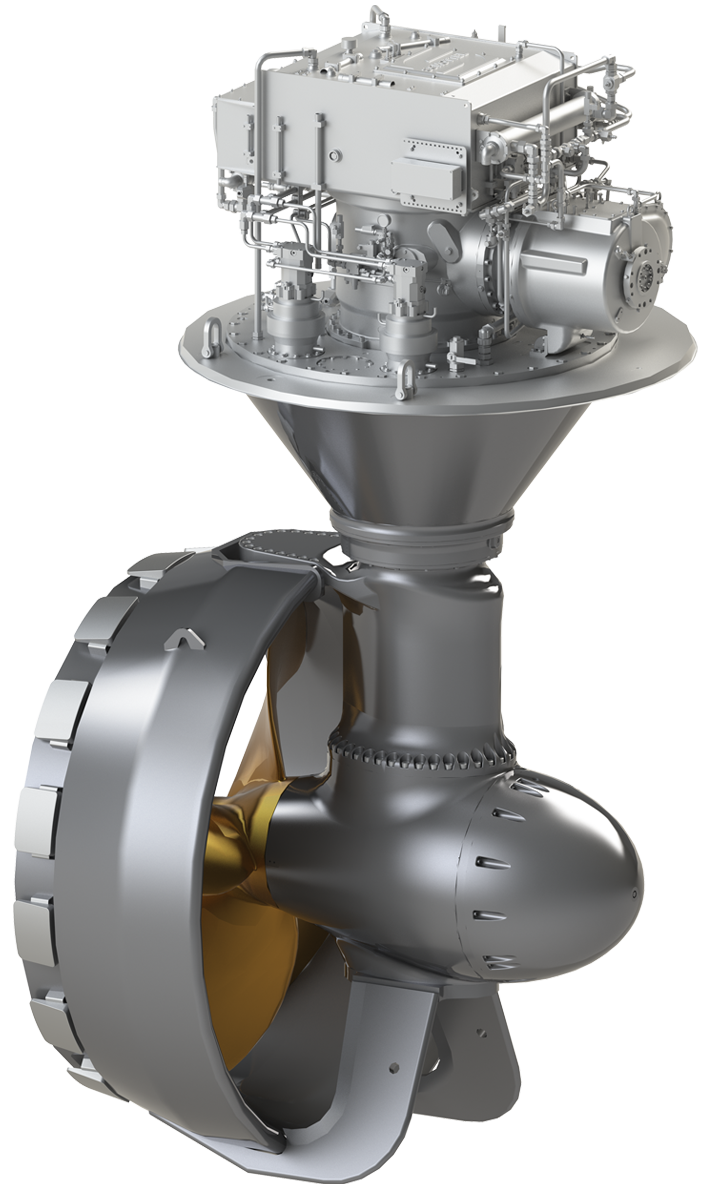

SCHOTTEL VarioDuct (SDV45)

The SDV45 combines proven higher efficiency during free sailing with excellent bollard pull values. In conjunction with optimally designed propeller geometries, the nozzle is able to fully utilize the outstanding performance values. Assuming the same propulsion power, the bollard pull is higher than the thrust of previous nozzles, while efficiency is significantly enhanced in the medium and higher speed range. This makes a major contribution to fuel savings.

The SDV45 is suitable for use in a wide range of operation profiles.

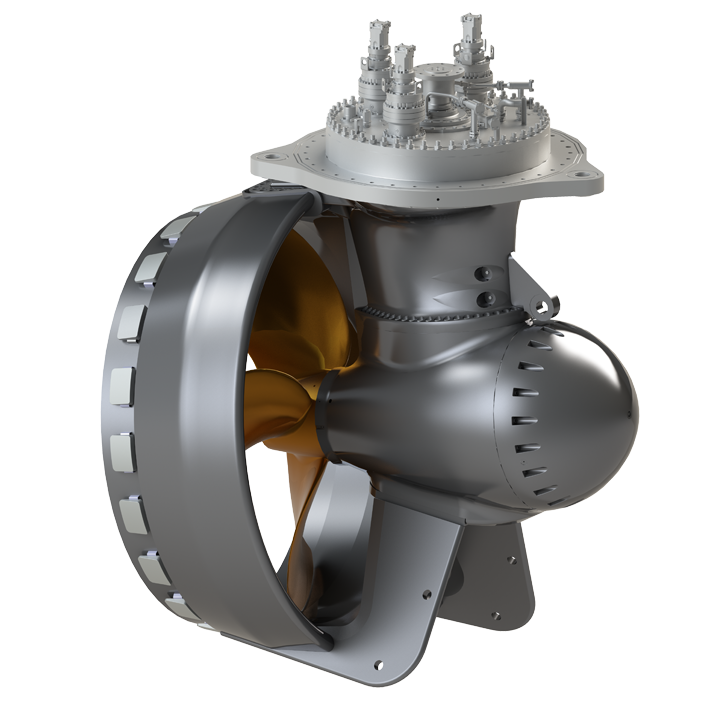

SCHOTTEL CruiseDuct (SDC40)

The SDC40 sets standards in terms of compact design and free sailing efficiency, thus also reducing operating costs compared to nozzles from other manufacturers. The high-performance nozzle is also characterized by optimally designed propeller geometries and outstanding performance features.

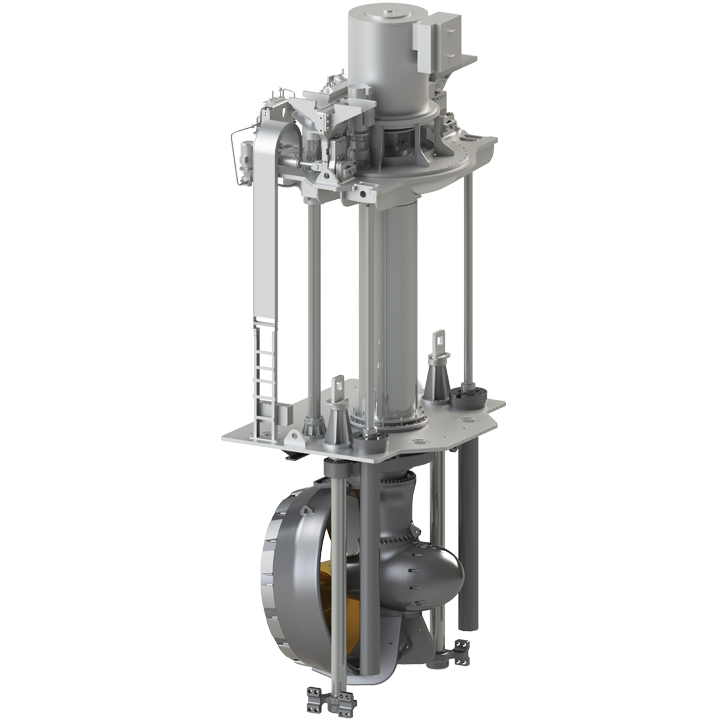

The nozzle has a particularly small outer diameter. This enables it to be optimally adapted to a wide range of ship designs and applications. At the same time, the high-performance nozzle is also suitable for conversions and upgrades with limited installation space. The SDC40 excels with the highest free sailing efficiency in transit at higher speeds. In addition, a higher maximum speed can be achieved.

Further nozzles are available on a project-specific basis.