In 1921, Josef Becker sets up a workshop in a small village on the Rhine. In 1950, his invention of the rudder propeller that is steerable through 360 degrees initiates a multitude of developments that allow SCHOTTEL to grow into a global company

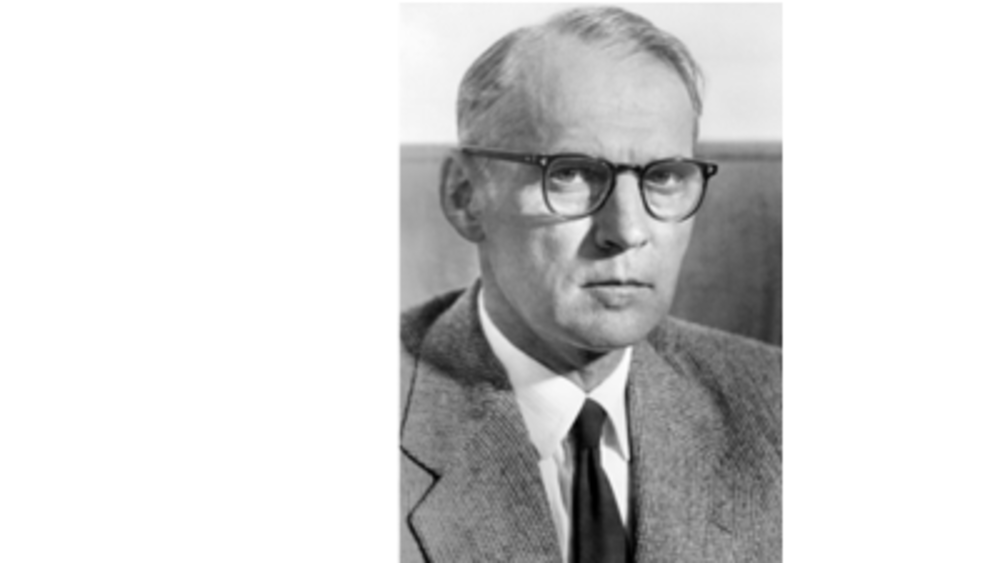

Josef Becker, the founder of today’s SCHOTTEL GmbH, is born on 14 July 1897. After finishing school, he starts an apprenticeship as a locksmith in his father’s smithy in Spay, Germany. This is followed by working in a shipyard in nearby Koblenz. Here, he acquires the shipbuilding expertise that, along with great craftsmanship and his visionary inventiveness, he will put to good use in his growing company.

After the First World War, in the midst of hyperinflation, Josef Becker registers his own locksmith’s business with the authorities. “When we founded the business, we may have had no money, but we had courage,” he later says reminiscently. 21 November 1921 is also the day of another life-changing decision: he marries Magdalena Karbach, whose commercial skills will make a major contribution to the success of the future SCHOTTEL shipyard. With a fundamentally new dinghy design—the sloop—Josef Becker succeeds in entering the boat building business in 1925.

The sloop production increases rapidly and the boat building range is expanded to include a variety of different motorboats. With the move into a spacious shipyard in 1934, Josef Becker meets the growing need for space. The new site is located at the SCHOTTEL river section, exactly at Rhine kilometre 578.5. To make sure that skippers familiar with the Rhine can locate it straight away, Josef Becker decides to rename his company SCHOTTEL-Werft. To this day, Spay is the company’s headquarters, which is continuously expanded until the construction of the new production site in Dörth in 2015.

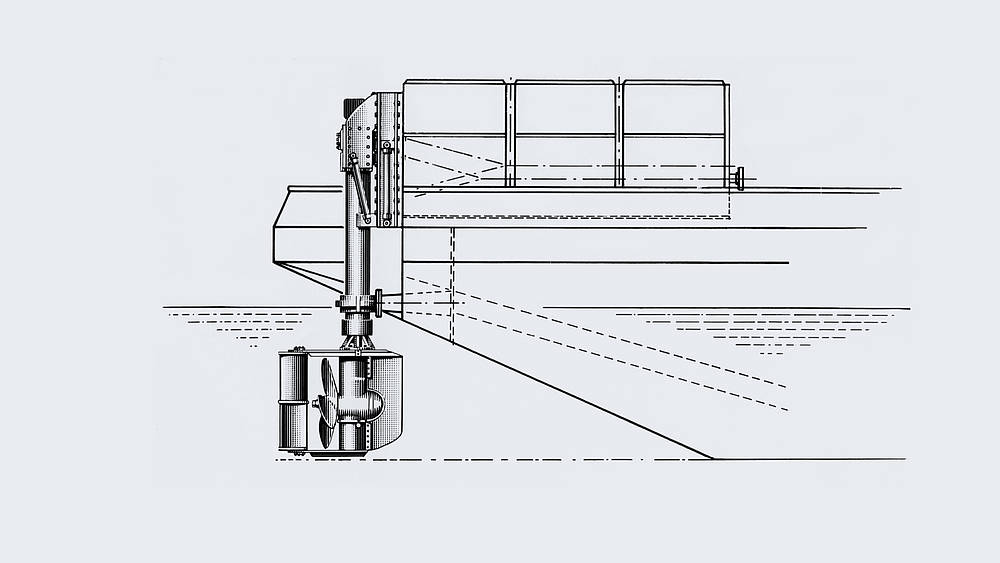

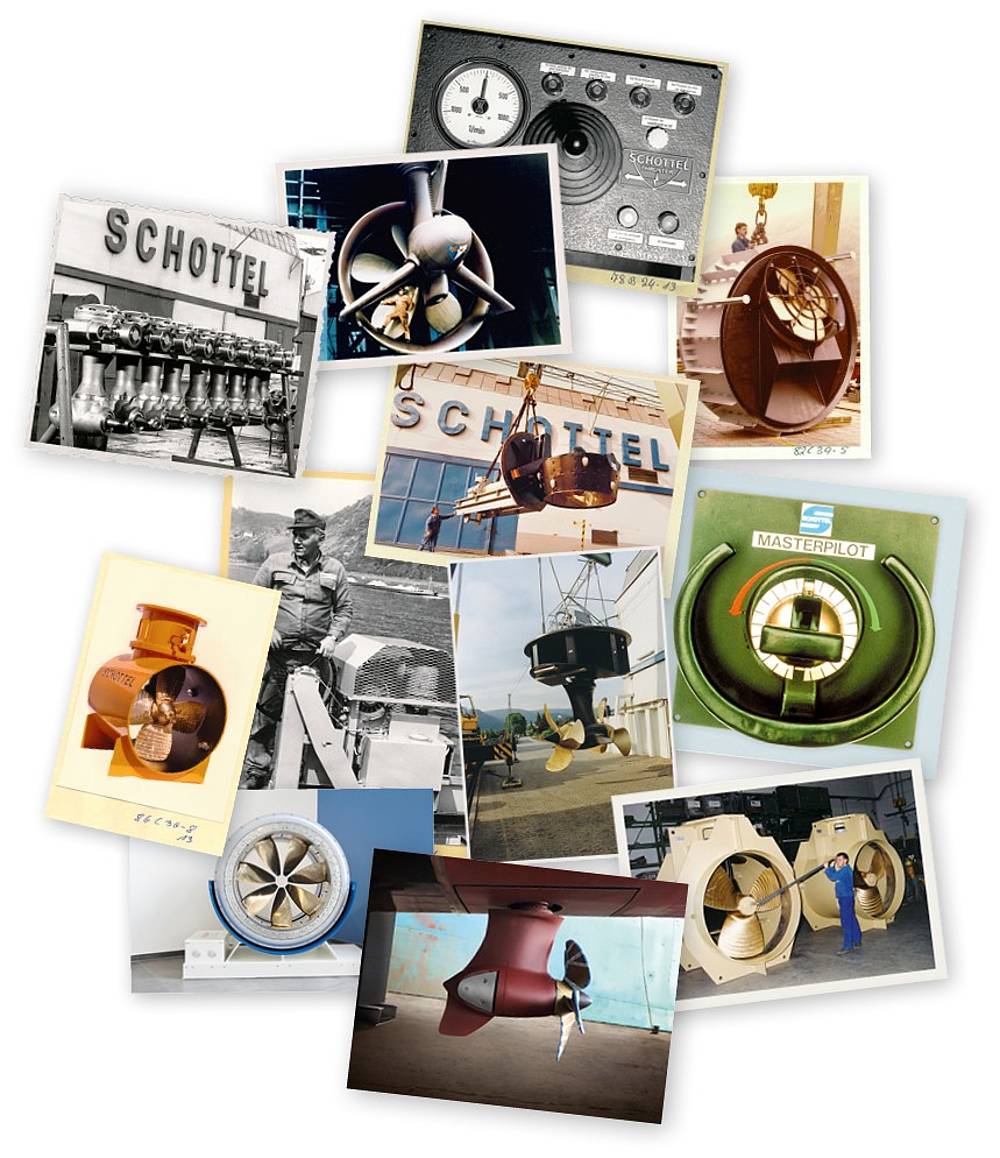

An innovative ship propulsion system, the first to combine steering and propulsion, paves the way for the future of Josef Becker’s company. The starting point for his ideas is the well-known outboard drive. He continues to make improvements to this drive until he designs a Z-drive without a separate rudder blade. Instead it has a propeller that can be steered 360 degrees around its own axis without any restrictions. His rudder propeller allows him to venture into completely uncharted territory: it enables a vessel to use the full power of its propulsion engine for manoeuvring. Domestic and foreign orders start pouring in in quick succession. In the 1960s, the emerging offshore industry demands larger and larger power units. Today, SCHOTTEL supplies approx. 20 types of power units ranging from 190 to 6,190 kW. Over the decades, all components have been optimized in terms of quality, flow behaviour, noise emissions and power density and have been equipped with numerous technical innovations.

While Josef Becker limits sales to the domestic market, partly due to a lack of foreign language skills, his son-in-law Franz Krautkremer focusses on internationalization. In 1958, the foundation of SCHOTTEL Netherlands in The Hague paves the way for it. In addition to France, sales territories on other continents are accessed by means of subsidiaries in the USA, the Far East and Brazil. Today, SCHOTTEL is represented in all of the world’s key shipping centers.

From the very beginning, customer proximity, expert advice and personal After Sales Service lie at the heart of the SCHOTTEL philosophy, actively exemplified by Josef Becker, who attaches just as much importance to customer service as he does to the production of high-quality propulsion units. Thanks to fast support, today’s service staff still ensures that downtimes are reduced to a minimum and vessels are ready for operation again as quickly as possible. In the past, the team communicated by letter, today it also has remote maintenance at its disposal.

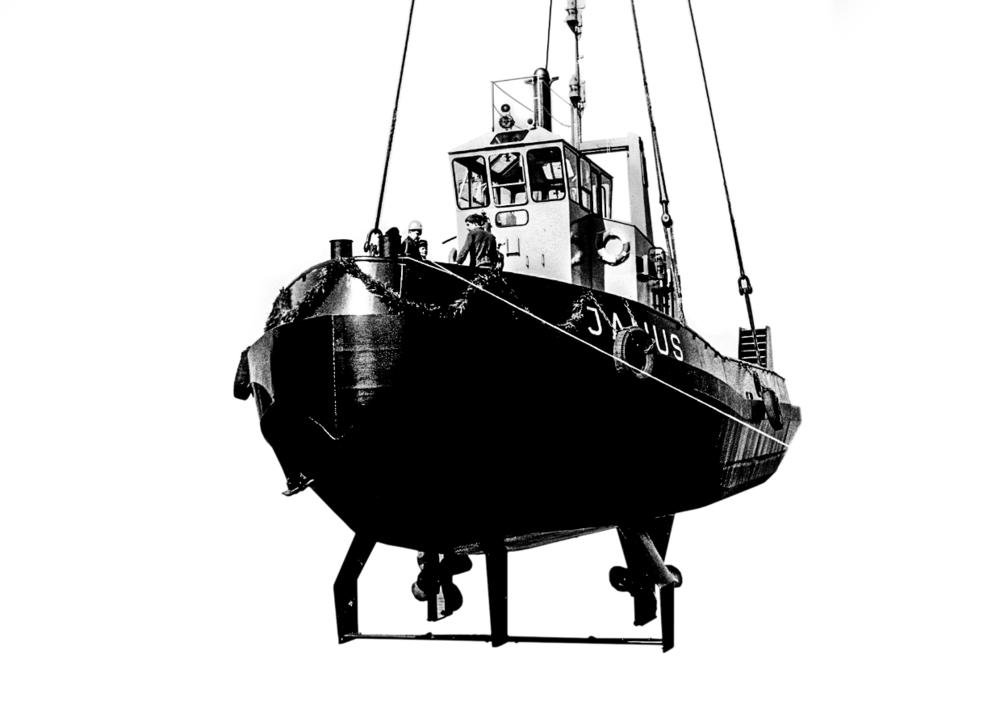

SCHOTTEL equips the first harbour tug with rudder propellers. Thanks to its exceptional manoeuvring capabilities, the Janus attracts attention and marks the starting point for a revolution in the pusher and tug boat market.

With the introduction of CAD software in design, the era of pen, paper and drawing board comes to an end after 60 years. Prior to the use of digital design models, project planning and the integration of propulsion systems into a ship’s design took several weeks—now, the process is completed in only a matter of days. Since then, continuous investments in research & development have always kept expertise and software at the highest level.

1981 sees the launch of the Masterpilot, a robust control module that particularly proves its worth in tugs. From 2001 onwards, the MasterStick is developed, a customized joystick system that allows up to six propulsion units to be manoeuvred with just one lever. Today, SCHOTTEL’s portfolio of cutting-edge propulsion control systems ranges from the hand-operated steering wheel directly on the propulsion unit to the remote-controlled, computer-assisted MasterStick.

In 1986, the shipyard receives its first spectacular large-scale ferry order for 96 rudder propellers for British ro-ro ferries. Time and again, SCHOTTEL has responded to the current requirements of the ferry industry with innovative propulsion solutions, positioning itself as the global leader. Since long before that, propulsion units from Spay have spearheaded the global tugboat market. During the offshore boom, which continues until 2015, the company secures a 20 percent market share in the platform supply vessel segment. Nowadays, SCHOTTEL products can be found on almost all vessel types. In addition to Tug & Offshore Energy and Ferries & Passenger Vessels, the company has a stable market position in the Merchant Vessels and Navy & Governmental segments: both for new vessels and modernizations. Automation, propulsion control and hybrid propulsion systems extend the product range which is supplemented by marine services.

SCHOTTEL takes over the company Wismarer Propeller und Maschinenbau GmbH (WPM), thereby expanding its product range to include controllable pitch propellers up to 30 MW. In addition, Wismar is now a production, testing and assembly site for particularly large SRP propulsion systems from 2 – 6 MW as well as for all retractable propulsion systems. Seven production and storage halls are available for this purpose on the 6-hectare site. Wismar has also established itself as an important service site.

In Spay, the SCHOTTEL Academy is founded as a training center for Service customers and staff. The aim of customer training is to provide crews with detailed knowledge enabling them to repair possible damages themselves and carry out maintenance tasks independently. This knowledge is imparted by means of 250 training modules with different content levels. In addition to Spay, Germany, three other locations now offer training and education: Houma, USA, Singapore, Fremantle, Australia. Another training center is being established in Itajaí, Brazil.

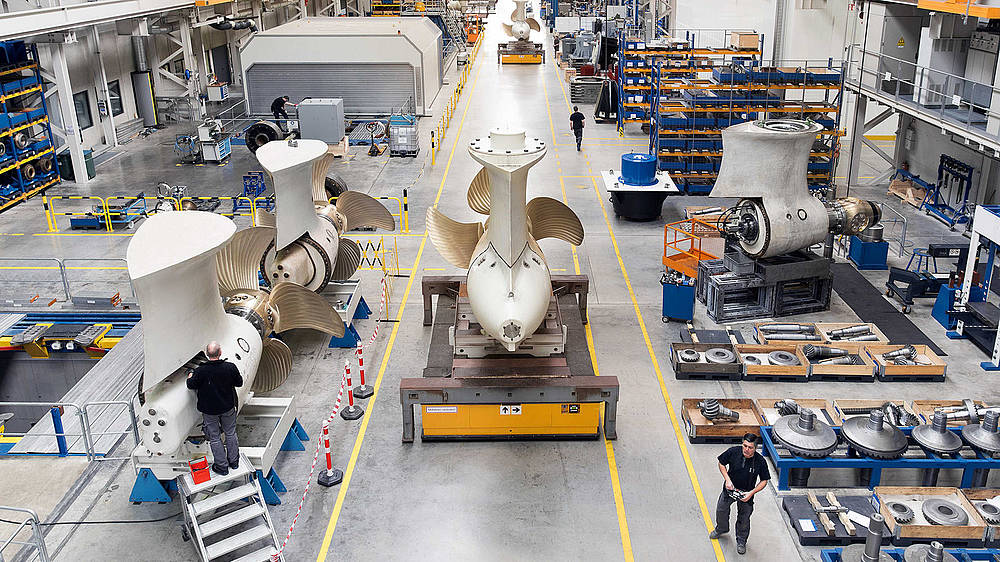

When Spay no longer offers any room for expansion, the decision is made for a new production site in nearby Dörth. With 23,000 square metres of production and office space, SCHOTTEL can both expand its vertical range of manufacture and increase its production capacity by around 30 percent. A modern apprentice workshop for the next generation, optimized production processes, a motivating working environment and committed environmental protection are the hallmarks of one of the most modern rudder propeller factories.

Within just a few years, the invention of the rudder propeller makes SCHOTTEL a world-renowned manufacturer of propulsion systems. It marks the start for developing an extensive portfolio that includes propulsion systems for a wide range of ship types as well as digital products. Today and in the future.