SCHOTTEL is investing heavily to expand its global logistics and repair infrastructure. This will offer customers shorter distances, faster response times and cutting-edge technology.

Every year, more than 500 propulsion systems of all sizes leave SCHOTTEL’s production sites, bound for destinations around the globe. And it’s not just the new build business that is experiencing significant growth; the after-sales segment is also benefiting from sustained momentum. Currently, over 10,000 vessels worldwide operate with SCHOTTEL systems – some with a single thruster, while others have multiple. Consequently, the demand for service and spare parts continues to rise steadily. In response to this growing demand, SCHOTTEL is launching three new workshop and logistics complexes in Germany, Brazil and Colombia. These new facilities will strengthen customer proximity, technical expertise, and sustainable site development. Customers will benefit from many enhancements, including significantly improved parts availability – even when supply chains elsewhere are unstable – as well as from improved service quality.

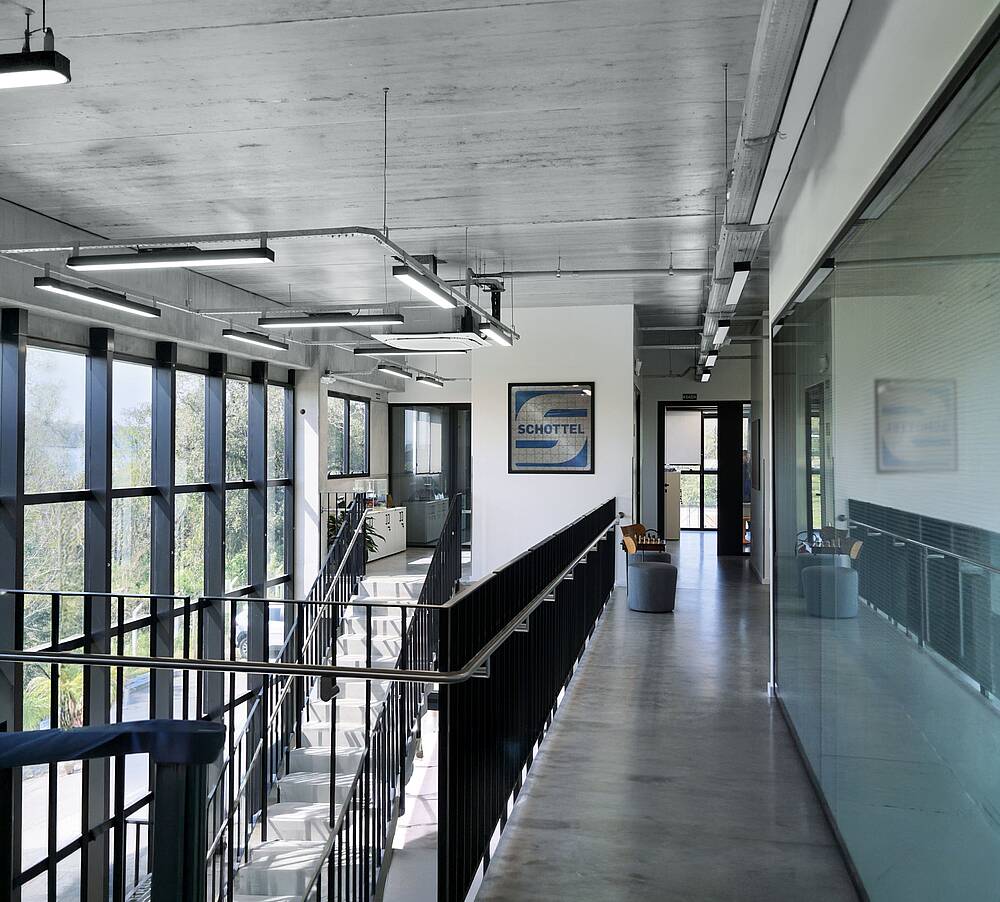

At SCHOTTEL’s production site in Dörth, a new logistics center is being commissioned. Connected directly to the existing facility, it offers 2,634 square metres of industrial floor space and 1,326 square metres of offices. An efficiently designed incoming goods processing system, cranes and a fully automated warehouse form the backbone of the state-of-the-art logistics setup designed to accelerate spare parts availability. The €10 million complex was built in accordance with sustainable construction criteria according to ESG specifications (Environment, Social, Governance). Regarding the shell and technology of the new building, the industrial insulation, heat pump technology and heat recovery system are all part of a high-quality sustainability concept. The new roof is structurally prepared to accommodate a photovoltaic system. This will further increase the 700,000 kWh of energy generated each year on the existing building. An adjoining three-storey office building provides space for employees in other departments.

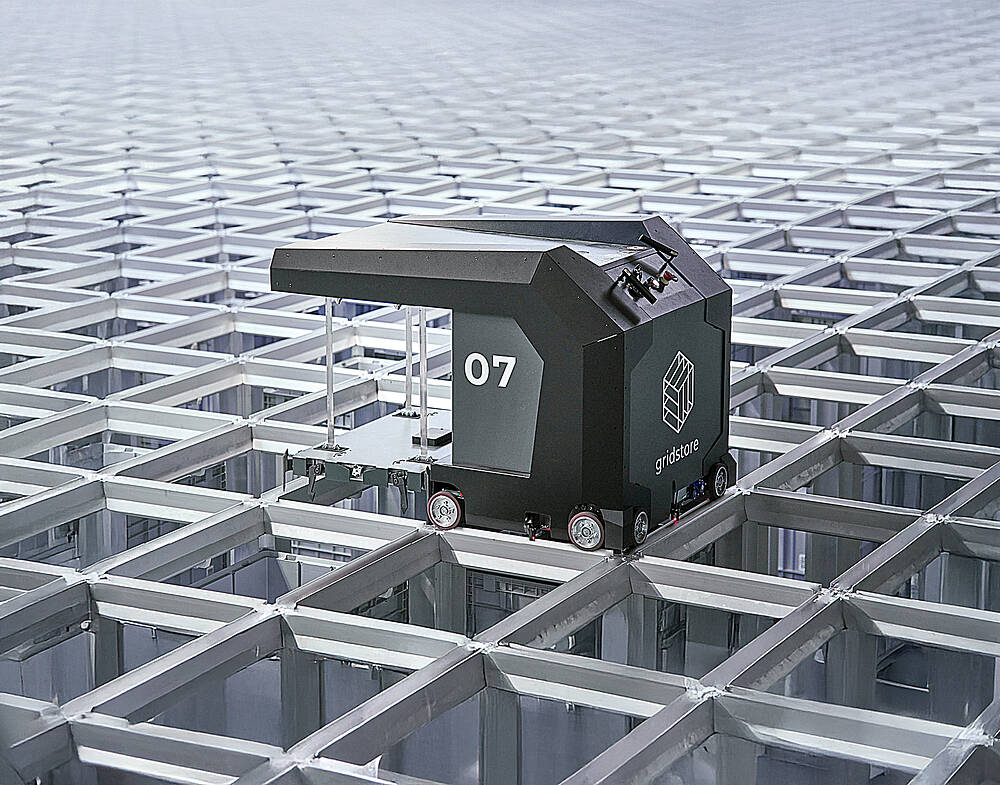

The automated Gridstore small parts warehouse offers a highly flexible solution for block-based storage of various container types, each up to 50 kg. A structure measuring just under 1,900 cubic metres provides 13,794 storage spaces for a maximum storage capacity of 90 percent. This corresponds to 12,414 containers being stacked, resulting in an exceptionally high storage density. Dynamic item sorting ensures efficient processes, with goods receipt and picking largely automated.

SCHOTTEL do Brasil is sending a strong signal on the occasion of its 50th company anniversary with the new building in Itajaí, Santa Catarina. A modern workshop with a warehouse, administrative offices, and training facilities has been built on a 10,500 square metre site. More than 2,700 original spare parts are kept on site to ensure fast, high-quality service. Resource-saving solutions such as rainwater treatment, wastewater and waste recycling, as well as a large-scale photovoltaic system underline the company’s commitment to sustainability. With sea logistics access via the port of Itajaí – the country’s second largest – the new facility strengthens proximity to customers in South America and expands the global service capacity of the SCHOTTEL Group.

Since its foundation in 1975, the former subsidiary with its own production facilities has evolved into a leading player in the maritime industry in Brazil and the neighbouring countries. SCHOTTEL do Brasil now manages newbuild sales and provides comprehensive after-sales services from its locations in Itajaí and Rio de Janeiro.

The new workshop fills a significant service gap in the Spanish-speaking Latin American market. Located on a 4,700 square metre site near major shipyards, the facility features a cutting-edge workshop and office space for up to 35 employees. Customers can expect a greatly expanded range of services, including OEM-level maintenance. To facilitate this, dual overhead cranes with up to 60-tonne lift[1]ing capacity, and 3D scanning for complex part evaluation are available. The spacious layout allows for the simultaneous servicing of multiple propulsion units, complemented by turning, milling, and grinding machines.

Cartagena is home to the only workshop operated by a propulsion manufacturer in Colombia, and it serves as the central service hub for 18 Spanish-speaking countries across Latin America. Its proximity to major shipyards and direct access to the Caribbean make it a key logistics center for technical consulting, spare parts supply, and training throughout the LATAM region.