Ships from Eastern Shipbuilding Group can be found from coast to coast in the United States and around the world. After 45 years, the shipyard has become one of the most diverse vessel construction companies in the United States with three main facilities along the coast of Florida's panhandle

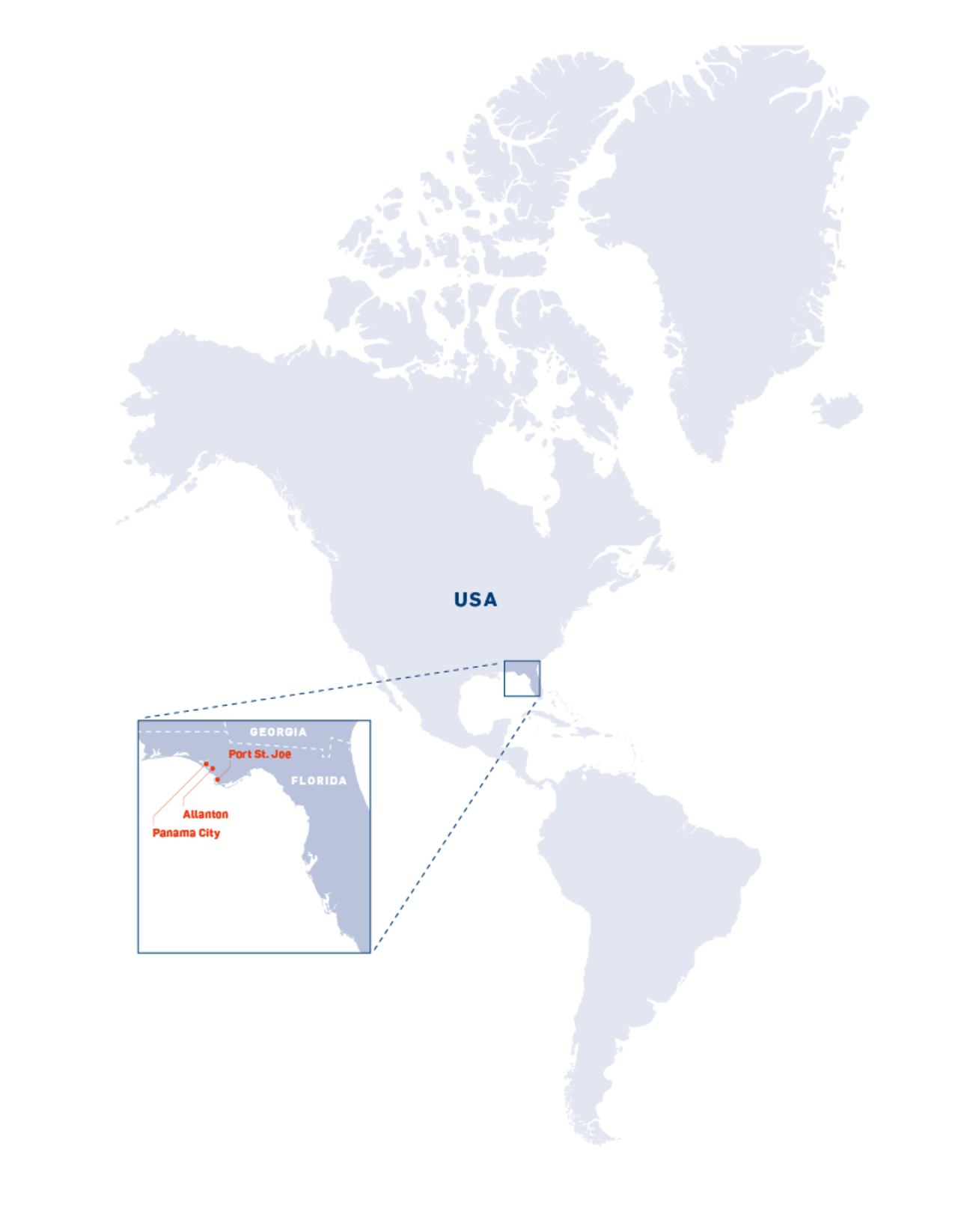

Headquartered in Panama City, Eastern Shipbuilding Group runs three locations: in Panama City, in Allanton, and in Port St. Joe. The business was founded by Brian R. D’Isernia in 1976 on one acre of leased property on Watson Bayou in Panama City. He had already taken a few steps in his career by then, including a law school degree. As a commercial longline fisherman, he learned firsthand that the only way to get the type of vessels he wanted was to design the vessels, write the specifications, and build them himself.

In the beginning, the order book featured relatively small longline commercial fishing vessels made of steel. After 45 years, Eastern Shipbuilding Group has become one of the most diverse vessel construction companies in the United States, with a large portfolio ranging from trailing suction hopper dredgers, tugs and towboats, nearly all kinds of passenger vessels, merchant carriers and more. "In 2016, the award for the USCG Offshore Patrol Cutters marked one of the most significant events in our company history as it was our entrance into the major government shipbuilding program," says Joey D’Isernia, President of Eastern Shipbuilding.

From only ten employees in 1976, and the first fishing boat named after the founder’s mother, the workforce has now grown to approximately 1,300 employees and contract workers across the three main shipbuilding facilities, making it the biggest employer along Florida’s panhandle. Since its beginnings, the company has established a portfolio of more than 350 vessels. Although most of them are Jones-Act-compliant and were built for US based companies, a remarkable number of foreign ¤ag vessels have been exported to locations such as Brazil, Colombia, and Canada.

The Nelson Street facility and operational headquarters in Panama City, is dedicated to the OPC project to ensure continuous and uninterrupted construction of those critical national security assets. This has allowed for process optimization and has resulted in enhanced producibility and lifecycle cost reductions for the USCG. Additionally, ESG has invested in the country’s first-ever on-site production facility to support the C5ISR system testing for this order. It is said to be the most technologically advanced telecommunications testing facility for marine vessels in the country. Nelson Street shipyard sits on 10 hectares (24 acres) and has over 600 metres (2,000 feet) of waterfront leading into St. Andrew’s Bay and out to the Gulf of Mexico. Among other assets, it is outfitted with three aluminium and steel production buildings, marine railways, and has a lifting capacity of 45 to 400 tonnes. The Allanton facility provides space for the commercial side of the business thanks to even greater dimensions. It boasts state-of-the-art steel processing equipment as well as project-supporting workshops such as a carpentry, warehouse, and a sandblasting & painting shop. Allanton shipyard houses the company’s administrative staff, together with personnel from engineering, project management, HR, etc.

Recently, a third main shipbuilding facility in Port Saint Joe, Florida, was opened. This yard is dedicated to the final outfitting and testing of newly constructed commercial vessels, as well as topside repairs. ESG has embarked on a $50 million, 15,000 tonnes dry-dock project to provide full vessel maintenance services for both commercial and governmental customers. ESG takes great pride in the fact that all facilities are ISO 14001 compliant. Processes and procedures serve to minimize the overall environmental footprint whether it is carbon emissions, keeping the waterways clean, or reducing waste through recycling.

Eastern has enjoyed a long partnership with SCHOTTEL that is represented by 63 joint projects including tugs, fire boats, platform supply vessels, multipurpose supply vessels, and heavy-lift crane vessels. President Joey D’Isernia: “We are proud to work with the best engineers and innovators in the industry. We partner with companies like SCHOTTEL who share our philosophy of quality and results and when we find those like-minded suppliers, we remain loyal to them.”

The shipyard is very familiar with the large SCHOTTEL product range such as the RudderPropellers, TransverseThrusters, CombiDrives, and ControllablePropellers. Some of the milestones in the partnership are projects such as the ten-vessel OSV series and two MPSVs for Hornbeck Offshore Services, the Boldini PSV in a series of five vessels, and tugs for McAllister Towing and Transportation. A particular highlight are the Harvey Gulf ships with SCHOTTEL RudderPropellers which won the prestigious Boat of the Year Award in 2017.

Since its founding, ESG has grown to be one of the top shipyards in the U.S. by reinvesting millions of dollars back into the business. It is still held privately as a multi-generational family business with Joey D’Isernia as president since 2015. He is one of six sons to founder and CEO Brian D’Isernia, with all six working in the firm. The company sticks to its origins and anchors itself to local culture and people in many ways. “Our community is our home, and we want to do our part to help it thrive,” comments Joey D’Isernia—At ESG, all signs point to the future.