How can underwater radiated noise (URN) be reduced? For over a decade, SCHOTTEL has been supporting various research projects and working closely with customers and partners to develop solutions for more sustainable shipping.

Reducing URN is becoming increasingly important in international maritime transport. The primary focus is on protecting marine life and ecosystems. However, quieter ship operations are also essential for enabling accurate acoustic measurements carried out by naval, research and oceanographic vessels. Furthermore, lower noise levels positively impact the physical and mental health of crew members and passengers.

To address these challenges, the International Maritime Organization (IMO) published revised, non-binding guidelines for reducing URN in July 2023. These guidelines not only support the development of technical and operational measures but also help assess potential impacts on the energy efficiency of vessels. Additionally, the IMO proposes future monitoring of URN which may lead to the implementation of thresholds alongside long-term monitoring requirements for specific regions.

But what actually causes URN? The reasons are varied. In addition to the gear meshing of propulsion systems, one of the main causes is cavitation on propellers: this occurs when water pressure drops below vapor pressure and small bubbles form. These bubbles collapse and generate pressure pulses that not only radiate sound into the water and the ship’s structure but can also reduce its efficiency and even damage the propeller while collapsing.

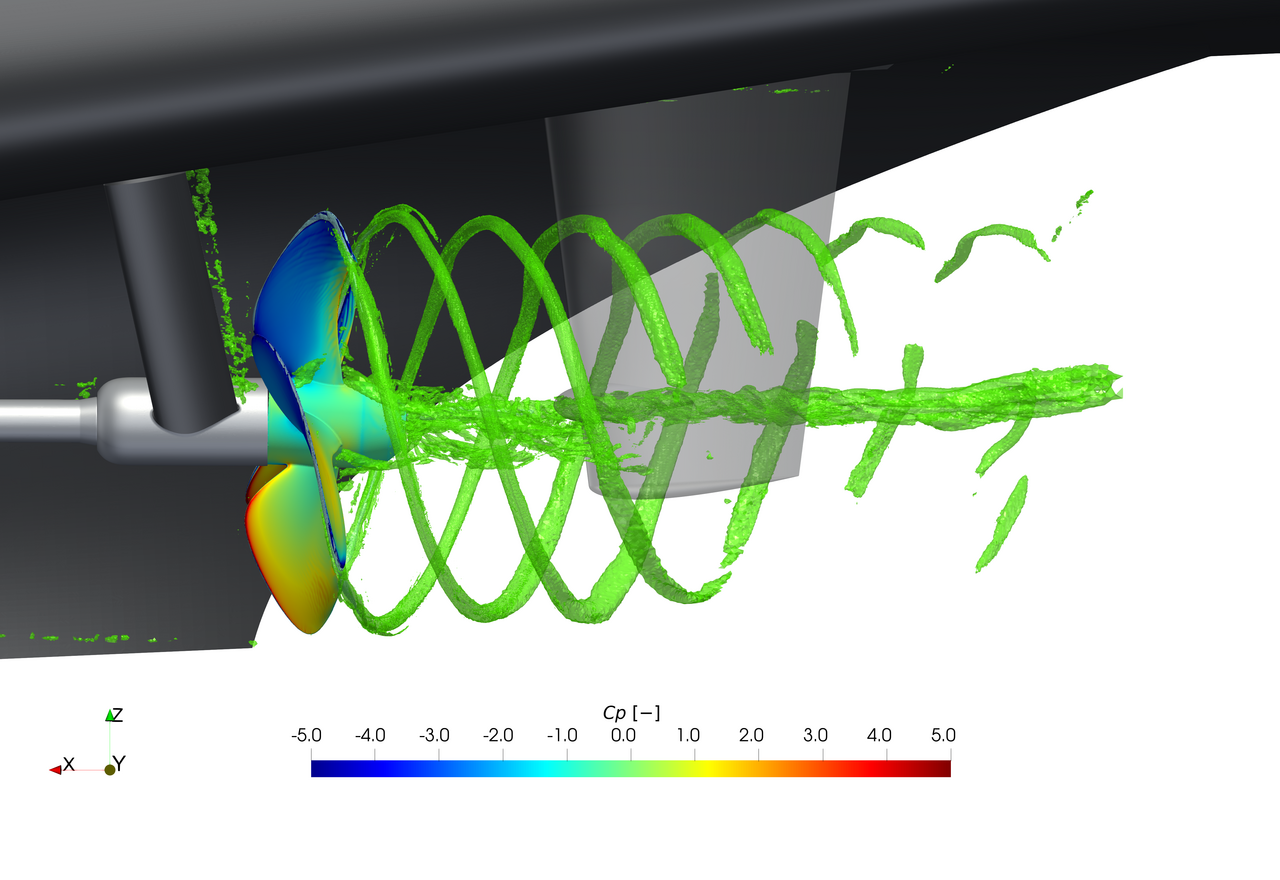

In order to minimize URN, SCHOTTEL uses CFD simulations during the design phase of propulsion systems. Computational Fluid Dynamics (CFD) has been an integral part of hydrodynamic design for years and is used to simulate the risk of cavitation and noise development, among other things. The insights gained are used to optimize the cavitation behaviour of the propeller. In addition, SCHOTTEL offers the support of model tests, in which reliable noise predictions are made and scaled up to the full-size version of the selected propulsion solution.

Furthermore, the company has been actively involved in a wide range of research initiatives for over ten years – beginning with ProNoVi (Propeller Noise Vibration). Within the scope of this project, SCHOTTEL and its research partners succeeded in improving numerical and experimental methods for predicting propeller-induced noise and in deriving practical recommendations for optimized product designs. Red-Emi (Reduction of hydroacoustic emissions from propulsion systems) takes this a step further. The initiative aims to increase the accuracy of noise predictions. This involves not only analyzing cavitating propellers using CFD simulations but also examining vortices and cavitation phenomena in the propeller wake as well as their interaction with surrounding structures. Additionally, the acoustic response to hydrodynamic alternating loads is investigated from a mechanical perspective. In contrast to previous research approaches, the dynamic vibration behaviour of the entire propulsion system is thus taken into account. These insights are used to optimize both the propeller design and the entire propulsion system: for example, the stiffness of selected components can be increased or reduced – with the goal of minimizing overall noise generation.

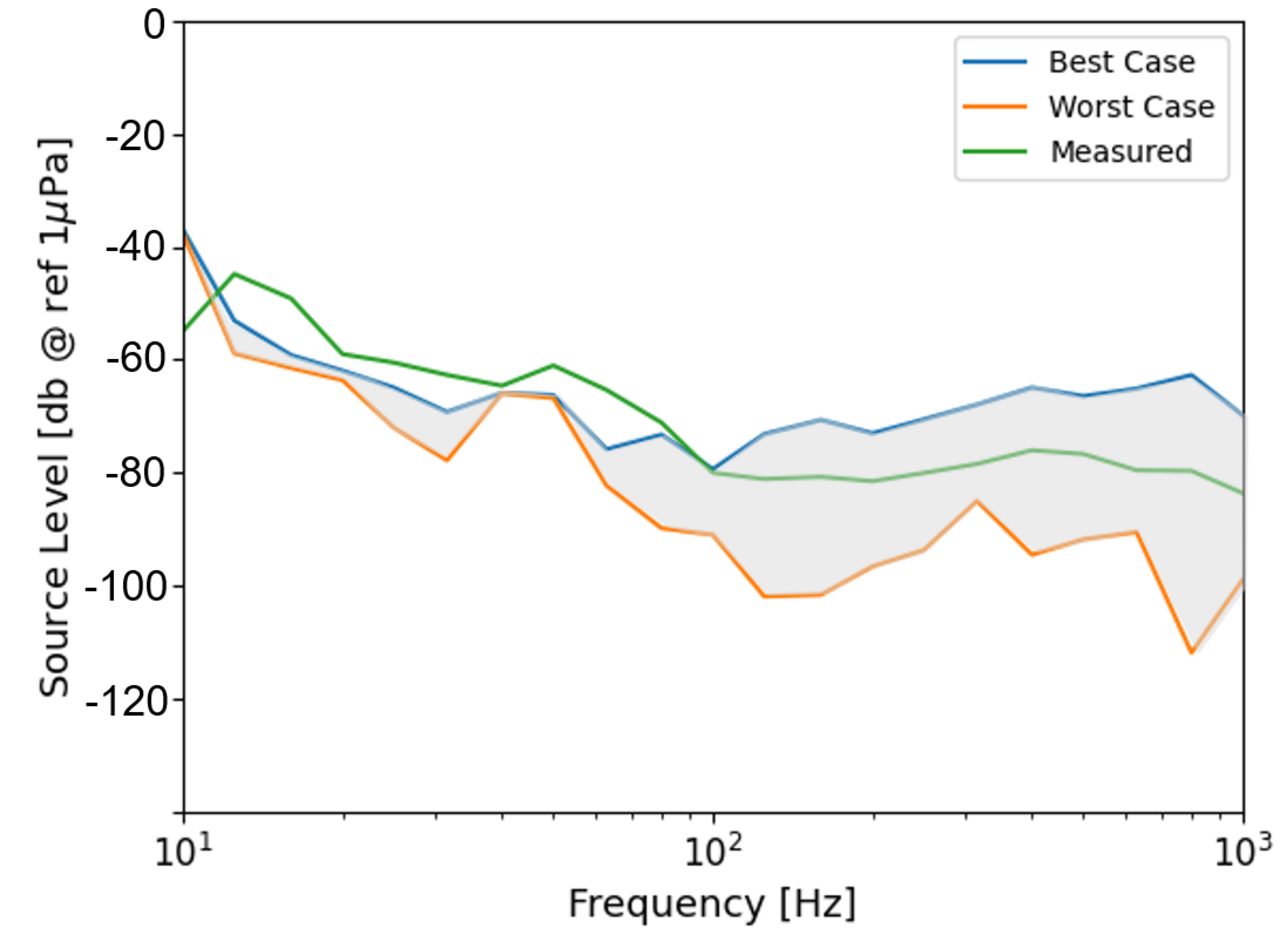

The research project HyPNoS (Hydrodynamic Propeller Noise Monitoring System) focused on existing propulsion systems. Together with the project funder Transport Canada and partner BC Ferries, SCHOTTEL investigated URN reduction on a series of Canadian double-ended ferries. The methods used included hull vibration analysis and underwater noise measurements using hydrophones. Through extensive research, a quantitative correlation between the vibrations and the emitted noise was established. Based on this pattern, SCHOTTEL engineers developed an algorithm for calculating and predicting URN in real time, taking into account factors such as propeller speed, pitch, vessel speed, and other input parameters. This algorithm served as the basis for a calibrated live URN monitoring system which was developed as a prototype and installed on board the ferries. Such feedback systems will enable operators to react to high URN levels during operation and initiate targeted noise reduction measures.

The research was carried out on vessels equipped with both original and retrofit propellers. This not only confirmed the applicability of the HyPNoS system but also demonstrated the effectiveness of retrofitting propulsion systems with noise-optimized propeller designs: despite a smaller propeller diameter of 4.7 metres instead of five metres, the retrofit solution achieved an average reduction in URN of five decibels.

The project’s advanced approach also gained recognition beyond the research community: HyPNoS has recently been named ‘Hydro-Efficiency Technology of the Year 2025’.

“These research projects have provided us with valuable insights into the analysis and prediction capabilities of URN,” summarizes Thorsten Tillack, Head of Hydrodynamics and Propeller Design at SCHOTTEL. “The data collected is already being incorporated into our product designs and is also paving the way for future developments. Together with our customers and partners, we are continuously working to reduce URN from ships and thus protect marine ecosystems and wildlife.”